Since its launch in 2003, CNG Services has been a leader in innovation in the gas industry and has made the transition from fossil natural gas to renewable gases, biomethane, Bio-SNG, and hydrogen.

In 2016 we were awarded a Queen’s Award for Industry: Innovation.

From 2020 we decided to only work on projects that contribute to reducing GHG and this is the key part of our ISO 14001 commitment and covers all our business activities.

In the past 10 years, our efforts have produced a material impact with an

estimated 20-year project life reduction in CO2 emissions of 17,500,000 tonnes

from the following projects:

Given the Net Zero requirement by 2050, we will continue to focus on the above areas but we will also develop new innovation projects

The following projects were made possible by a number of innovations

pioneered by CSL which will continue to support a low-carbon future.

First ever self lay and CNG station connection to the NTS including trialing processes and documentation, successfully adopted by National Grid. Prepared a Major Accident Prevention Document (MAPD) and Safety Case Exemption for the pipeline taking gas from the NTS to supply the ‘mother station’

Somerset Farm

First use of Soluforce in a GB high-pressure gas project, which represents an important development as this pipeline material is likely to be very useful for Hydrogen applications.

First UK Reinforced Thermoplastic (RTP) NTS connected private pipeline.

Created UK’s First Biomethane Injection Project.

First use in GB of biomethane upgrading unit with CO2 capture (brought to UK by CSL).

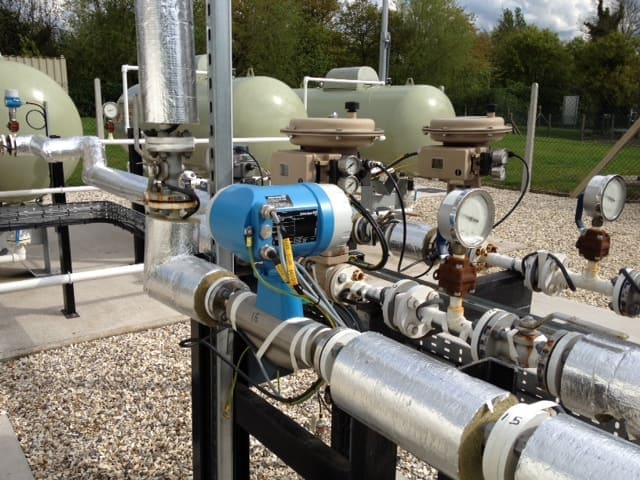

First Biomethane Injection connection to the Local Transmission System (LTS) Self Lay Project.

First UK Reinforced Thermoplastic (RTP) LTS pipeline.

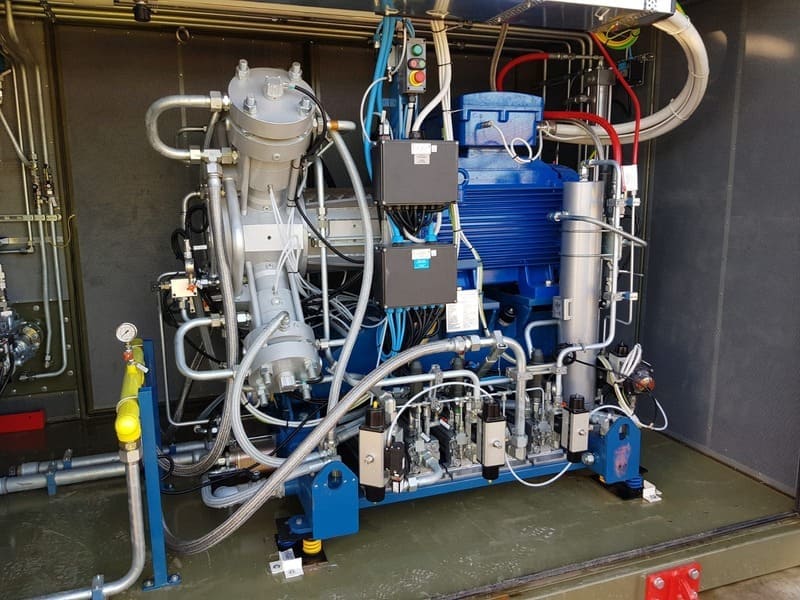

First biomethane site with remote compressor (7 km of 6.9 bar pipeline to the compressor which is located at the LTS).

First use of UMOE Type 4 glass fibre CNG/CBM trailer for biomethane in GB.

Design and installation of the first compressed biomethane dispenser system directly from the biogas upgrading plant.

First CNG station connection to the LTS.

Please fill in the contact form below and a member of the team will be in touch with you shortly.